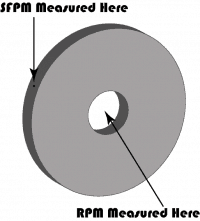

In the world of grinding, there are two measures for speed that you need to know and understand how they affect one another.

RPM and SFPM.

RPM = Revolutions Per Minute; defined as the number of complete axis turns per minute

SFPM = Surface Feet Per Minute; defined as the distance any one abrasive grain on the cutting surface travels per minute.

The basic equation is:

SFPM = Wheel Diameter in inches x RPM x 0.262

Why is this important?

As your grinding wheel wears, the SFPM will decrease. To maintain the same grinding characteristics, you’ll want to maintain the SFPM. In order to maintain the SFPM you need to increase the RPM.

Okay, that sounded like a lot of gibberish, didn’t it? Here’s an example that should clear things up:

Grinding Wheel Diameter = 24″, Machine Speed = 600 RPM; SFPM = 3772.8. As the wheel wears to, say, 21″, SFPM will slow to 3144 if RPM stays at 600. To maintain 3772.8 SFPM the RPM will need to be increased to 720.