Can your dust collector be exposing you to a fire risk? According to dustsafetyscience.com, “dust collectors are responsible for nearly 15 percent of industrial fires and explosions in North America…” Implementing a strategy for fire prevention and suppression in industrial dust collectors is key to keeping employees and facilities safe for fabricators and manufacturers.

Starting and sustaining a fire inside a dust collector requires three elements – fuel, oxygen and ignition. Together, these three elements are known as the “fire triangle.” Removing any one of them will prevent a fire from starting or spreading. Dust collectors provide an ideal environment for a fire. They have plenty of fuel and lots of airflow. All it takes is a spark from an industrial process, heat or sparks from the dust collector blower/motor, or even static electricity.

Spark Control

While a facility can’t necessarily avoid oxygen or flammable material, it can control sources of ignition, such as sparks from welding, cutting, grinding, electroplating and other industrial processes. Spark control can be passive or active. Passive systems physically block the passage of sparks, slow down airflow enough to allow sparks to drop out naturally or use centrifugal force to strip the thermal envelope from the spark. Active systems use sensors to detect the presence of hot sparks and use a sprinkler or jet system to extinguish them using water or a chemical. These systems are most commonly used in high-risk applications, such as highly combustible dust or an explosive atmosphere. A centrifugal spark arrestor is a good choice for most spark producing applications. These devices extinguish sparks by creating a spinning pathway that forces them against the sidewalls of the spark arrestor.

Fire Detection

Every dust collector should be equipped with a fire/smoke detector that sounds an alarm if a fire starts inside the collector. Ideally, the system will also shut down the blower to stop the flow of air that feeds the fire.

Fire Suppression

All dust collectors should be equipped with a fire suppression system in case a fire breaks out inside the collector. There are three main options when it comes to fire suppression.

- A water sprinkler system. This is a simple and cost-effective fire protection method.

- CO2 smothers a fire by displacing oxygen in the filter chamber. This method suppresses fires and prevents them from spreading. It does not necessarily extinguish the fire. This method is not safe for use in indoor areas where humans or animals are present.

- Chemical fire suppressants include foams, dry chemical agents and clean-agent gas systems. Clean-agent gas works by suppressing the fire rather than extinguishing it. Unlike foams or dry chemicals, it does not leave a residue on equipment and is safe for use around electronics. Many clean-agent gases can be safely used in areas where people or animals are present.

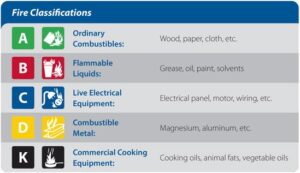

Fire Classifications

The most important consideration in choosing a fire suppression system is the type of fire that will need to be extinguished. The National Fire Academy categorizes fire into five classes based on the type of fuel present.

Most dust collector fires fall into Class A, ordinary combustibles, which can be put out using the three methods outlined above. If combustible metal dust such as magnesium, titanium or aluminum are present or if flammable gases or liquids are mixed in with the dust, the facility can be at risk for a Class B or Class D fire in its dust collection system. If the possibility of a Class B or Class D fire exists in your facility a knowledgeable system engineer should be employed to determine the best fire suppression option.